Popular Tablet Coating Machine Manufacturers in Mumbai

Popular Tablet Coating Machine Manufacturers in Mumbai – Complete Guide by Bombay Engineering Works

If you are searching for the most popular Tablet Coating Machine Manufacturers in Mumbai, you’re probably looking for reliability, engineering excellence, and a brand that understands the nuances of pharmaceutical processing. Mumbai is the heart of India’s pharma equipment manufacturing industry, and among the top names, Bombay Engineering Works stands tall with decades of trust, unmatched expertise, and world-class machinery.

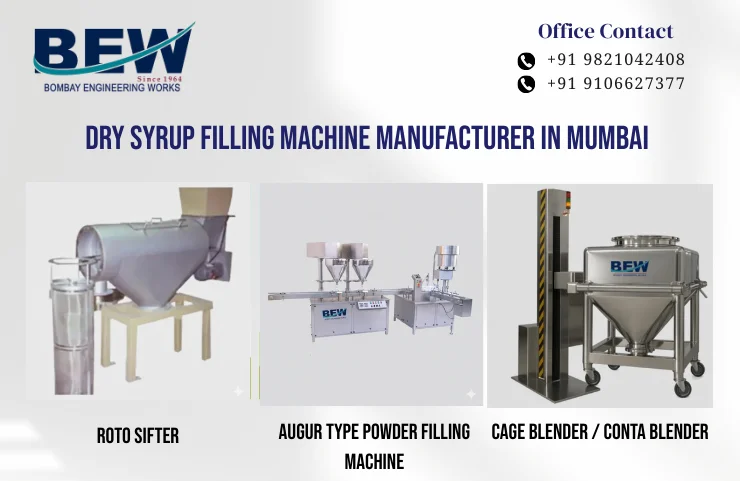

Established in 1964, Bombay Engineering Works has been a pioneer in providing advanced Pharmaceutical Machinery, Chemical Machinery, Food Processing Machinery, Cosmetic Machinery, and Ayurvedic & Herbal Machinery. With a strong commitment to quality, innovation, and customer satisfaction, we have built a legacy that continues to serve clients across India and around the world.

What Is a Tablet Coating Machine?

A tablet coating machine is specialized pharmaceutical equipment designed to apply a uniform coating layer to tablets. This coating could be for various purposes appearance enhancement, protection, controlled release, taste masking, or branding.

Tablet coating is a critical process, especially in high-volume pharmaceutical environments where precision and consistency matter. These machines ensure that each tablet receives the same thickness and quality of coating, improving both product appearance and performance.

Key Functions of Tablet Coating Machines

- Coating tablets with polymers or sugar solutions

- Drying tablets during the coating process

- Ensuring uniform coverage

- Enhancing aesthetics and protection

- Supporting sustained or controlled drug release

With the growing demand for coated tablets, industries rely heavily on reliable tablet coating equipment to maintain quality standards.

Why Tablet Coating Is Important in Modern Pharma Manufacturing

Tablet coating is far more than just adding an aesthetic layer. It has multiple functional and performance-based benefits :

Improves Tablet Swallowability

Coatings make tablets smoother and easier to swallow.

Protects Active Ingredients

Coating layers shield sensitive ingredients from moisture, heat, or light.

Taste and Odor Masking

Unpleasant taste can be masked using polymer-based coatings.

Branding and Identification

Logos, colors, and imprints can be applied for easy brand recognition.

Controls Drug Release

Coatings are often used to deliver controlled or sustained release formulations.

Enhances Durability and Shelf Life

Coated tablets are more resistant to breakage and environmental conditions.

Given these benefits, pharmaceutical companies seek dependable coating machines that can deliver consistent results every time which is where trusted manufacturers come in.

Types of Tablet Coating Machines

Tablet coating machines come in various configurations, each designed for specific coating needs and production scales.

1. Conventional Coating Pan

This is the oldest and most widely used tablet coating system. It consists of a rotating pan where tablets tumble and coating solutions are sprayed.

Advantages

- Simple design

- Easy to operate

- Cost-effective

- Suitable for sugar and film coating

2. Perforated Coating Pan (Auto Coater)

A perforated pan allows hot air to pass through the tablets, ensuring faster and uniform drying.

Advantages

- Ideal for large-scale production

- Efficient drying capability

- Better film formation

- Shorter coating time

3. Fluid Bed Coaters

These machines suspend tablets in an airflow while applying the coating.

Advantages

- Very uniform coating

- Fast processing

- Ideal for moisture-sensitive tablets

- Great for advanced film coatings

4. Lab-Scale Coaters

Used for research, development, and small-batch production.

Advantages

- Ideal for pilot batches

- Helps in formulation development

- Lower material wastage

5. High-Efficiency Coaters (HCOAT Systems)

Advanced automatic systems designed for modern, high-capacity pharma plants.

Advantages

- Fully automated

- Minimal human intervention

- Precise coating thickness

- Reduced energy consumption

Features of a High-Quality Tablet Coating Machine

When choosing a machine from popular tablet coating machine manufacturers in Mumbai, here are the essential features to look for:

Uniform Coating Technology

Ensures consistent coating across all tablets.

Efficient Drying System

Prevents sticking or uneven layers.

Advanced Spraying System

Atomization and angular spraying for even distribution.

Stainless Steel Body

Ensures hygiene and meets pharma-grade standards.

Easy Cleaning (CIP/SIP Options)

Improves efficiency and reduces downtime.

Automation and Control Panels

PLC-based control systems for accurate process control.

Safety Features

Auto-shutoff, emergency stop, temperature monitoring, etc.

These features form the backbone of reliable and high-performance tablet coating machines.

Why Mumbai Is a Hub for Tablet Coating Machine Manufacturing

Mumbai is home to some of India’s best engineering and pharmaceutical equipment manufacturing companies. This is due to :

- Established industrial infrastructure

- Skilled workforce

- Access to global markets

- Strong supply chain for pharma equipment

- Long-standing industry reputation

Bombay Engineering Works is one of the most respected names contributing to this legacy since 1964.

Bombay Engineering Works : A Trusted Name Since 1964

For over six decades, Bombay Engineering Works has been at the forefront of manufacturing premium-quality pharmaceutical machinery. Our experience, backed by a commitment to innovation and customer satisfaction, has earned us the trust of thousands of clients in India and abroad.

Our Product Range Includes :

- Tablet Coating Machines

- Capsule Filling Machines

- Blenders and Mixers

- Fluid Bed Dryers

- Granulation Machinery

- Chemical and Cosmetic Machinery

- Food Processing Machinery

- Herbal and Ayurvedic Machinery

Why Choose Bombay Engineering Works?

1. 60+ Years of Manufacturing Excellence

Since 1964, we have consistently delivered top-quality engineering solutions.

2. Advanced Engineering and Design

Our machines are built using precision engineering and modern technology.

3. High-Durability Materials

We use premium stainless steel and pharma-compliant components.

4. Custom Solutions

Tailored machinery for small-scale, mid-size, and large pharmaceutical units.

5. Strong After-Sales Support

We provide installation, training, maintenance, and spare parts support.

6. Competitive Pricing

High-quality machinery at industry-best pricing.

7. Global Reach

We supply machinery across India and to international markets.

Applications of Tablet Coating Machines

Tablet coating machines manufactured by Bombay Engineering Works are used widely in:

Pharmaceutical Industry

Coating candies, pellets, seeds, and more.

Nutraceuticals

For film, sugar, and enteric coating.

Ayurvedic & Herbal Units

Protective and aesthetic coating for herbal tablets.

Food & Confectionery

Coating candies, pellets, seeds, and more.

Chemical Industries

Coating industrial pellets or granules.

Our versatile and robust design makes them suitable for diverse industries.

Step-by-Step Tablet Coating Process

Here is a simplified breakdown of how tablet coating works:

1. Loading the Tablets

Tablets are fed into the coating pan.

2. Pre-Heating

Tablets are pre-warmed to ensure proper adhesion.

3. Spraying the Coating Solution

Atomized spray ensures even coverage.

4. Drying

Hot air circulates to dry the coating instantly.

5. Continuous Rotation

The pan rotates to tumble and mix tablets for uniformity.

6. Cooling and Unloading

Finished tablets are cooled and discharged.

With our automated systems, this entire process becomes smooth, efficient, and repeatable.

How to Choose the Right Tablet Coating Machine Manufacturer

Experience and Expertise

Longevity in the industry speaks volumes.

Quality of Raw Materials

Pharma-grade stainless steel is essential.

Manufacturing Standards

Machines should comply with cGMP, FDA, and WHO guidelines.

Customization Capability

Every production unit has different requirements.

After-Sales Service

A reliable support team is crucial for maintenance and troubleshooting.

Transparency in Pricing

You should know what you’re paying for.

Bombay Engineering Works excels in all these areas.

Advantages of Buying Tablet Coating Machines from Bombay Engineering Works

Superior Coating Performance

Designed for precision, consistency, and efficiency.

Reduced Processing Time

High-efficiency drying systems shorten batch cycles.

Energy Efficient

Our machines consume less power while delivering better output.

Easy to Clean and Maintain

CIP/SIP options and ergonomic design.

User-Friendly Control Systems

Digital, PLC-based controls for smooth operation.

FAQs – Popular Pharmaceutical Machine Manufacturers in Mumbai

Q1. What is the purpose of a tablet coating machine?

Ans: It applies a protective or functional coating layer to tablets, improving their appearance, durability, taste, and performance.

Q2. Do you offer customization in tablet coating machines?

Ans: Yes, Bombay Engineering Works provides fully customizable designs based on batch size, coating type, and production needs.

Q3. Are your machines compliant with pharma standards?

Ans: Absolutely. Our machines meet cGMP, FDA, and WHO-GMP requirements.

Q4. Do you provide installation and maintenance support?

Ans: Yes. We offer installation, training, maintenance, and spare parts support.

Q5. How can I contact Bombay Engineering Works?

Ans: You can call us directly at 9821042408 for inquiries.

Contact Bombay Engineering Works Today

Address: Unit No. 9, Unity Industrial Estate, Naikpada, Valiv Village, Near Ganesh Mandir, Vasai East, Dist: Palghar-401208.

Phone: +91 9821042408 / +91 9106627377

Email: info@bombayengg.com / admin@bombayengg.com / support@bombayengg.com

Website: www.bombayengg.com

Conclusion

When it comes to choosing the most popular Tablet Coating Machine Manufacturers in Mumbai, Bombay Engineering Works has earned its reputation through decades of excellence, engineering precision, and customer trust. With a rich history dating back to 1964, we continue to deliver cutting-edge machinery that supports the pharmaceutical and allied industries.

Whether you’re setting up a new production line or upgrading your existing equipment, our tablet coating machines offer unmatched performance, durability, and value for money.

For inquiries and quotations, call now: 9821042408.

If you want reliable machinery, expert guidance, and long-term service support, Bombay Engineering Works is your ideal partner.