Dry Syrup Section Machinery Manufacturers in Vasai

Dry Syrup Section Machinery Manufacturers in Vasai – Your Trusted Partner for Pharmaceutical Excellence | Bombay Engineering Works

In today’s fast-evolving pharmaceutical manufacturing landscape, precision, hygiene, automation, and regulatory compliance are no longer just expectations they’re necessities. Manufacturers across India and worldwide are increasingly shifting toward advanced production lines that deliver accuracy, consistency, and long-term reliability. When it comes to Dry Syrup Section Machinery Manufacturers in Vasai, one name has been consistently winning the trust of industry leaders for decades Bombay Engineering Works.

Founded in 1964, Bombay Engineering Works (BEW) stands as one of India’s most respected and technologically advanced manufacturing companies serving the Pharmaceutical, Chemical, Food Processing, Cosmetic, Ayurvedic, and Herbal industries. With nearly six decades of expertise, BEW has been innovating, designing, and delivering world-class machinery that empowers businesses to achieve higher efficiency, productivity, and compliance.

Whether you’re a start-up pharmaceutical unit in Vasai or an established multinational company, you need machinery that delivers precision filling, minimal wastage, contamination-free processing, ergonomic operation, and full compliance with GMP, WHO, and FDA guidelines. This is exactly what Bombay Engineering Works provides.

What Is a Dry Syrup Section? A Quick Overview

The dry syrup section in pharmaceutical manufacturing refers to the processing line where powders and granules are handled, filled into bottles, sealed, labeled, and prepared for final packing. Dry syrups are commonly used in pediatric and antibiotic formulations. They require extremely precise dosing to maintain therapeutic effectiveness.

A well-designed dry syrup production line ensures:

- Accurate weight dosing

- Zero product wastage

- Contamination-free filling

- Speed and efficiency

- Compliance with global standards

- Minimal human intervention

About Bombay Engineering Works (BEW)

Established in 1964, BEW is one of India’s most respected manufacturers of:

- Pharmaceutical Machinery

- Chemical Machinery

- Food Processing Machinery

- Cosmetic Machinery

- Ayurvedic & Herbal Machinery

With world-class infrastructure, expert engineers, and a global clientele, BEW continues to be a pioneer in advanced machinery manufacturing.

For inquiries, reach out at:

Call : 9821042408

Visit : www.bombayengg.com

Why Bombay Engineering Works Is the Leading Dry Syrup Section Machinery Manufacturer in Vasai

Established in 1964, BEW has earned its reputation because of unmatched experience, high-quality manufacturing standards, and more than 50+ years of engineering innovation. Here’s why the brand is trusted globally:

1. Decades of Expertise in Precision Engineering

Very few companies in India have been operational for nearly 60 years in pharmaceutical machinery manufacturing. BEW’s vision of building machines that stand the test of time makes it a preferred choice.

2. State-of-the-Art Manufacturing Facility in Vasai

Located in the industrial hub of Vasai, the facility is equipped with:

- CNC machining

- Advanced fabrication

- Laser cutting

- Precision polishing

- Quality inspection units

- Dedicated R&D division

This ensures high-quality, durable, and GMP-compliant machinery.

3. Customizable Dry Syrup Machinery Solutions

Every pharmaceutical company has unique production needs. BEW provides:

- Small batch production lines

- Medium-level automated lines

- Fully integrated high-capacity dry syrup filling systems

Custom engineering is one of their strongest capabilities.

4. 100% Compliance with Global Standards

All machines comply with:

- cGMP

- WHO guidelines

- US-FDA norms (where applicable)

- ISO certification standards

This ensures your final output meets global pharmaceutical norms.

5. Easy Operation and Low Maintenance

Machines are designed for:

- User-friendly controls

- Quick changeover

- Low maintenance cost

- Long operational life

6. Excellent After-Sales Support

From installation and validation to AMC and troubleshooting, the expert team is always available at 9821042408.

7. Trusted by Pharmaceutical Giants

With decades of relationships across the pharma sector, BEW has become the preferred partner for:

- Antibiotic manufacturers

- Pediatric medicine units

- Nutraceutical companies

- Herbal & Ayurvedic manufacturers

- Contract manufacturing units (CMOs)

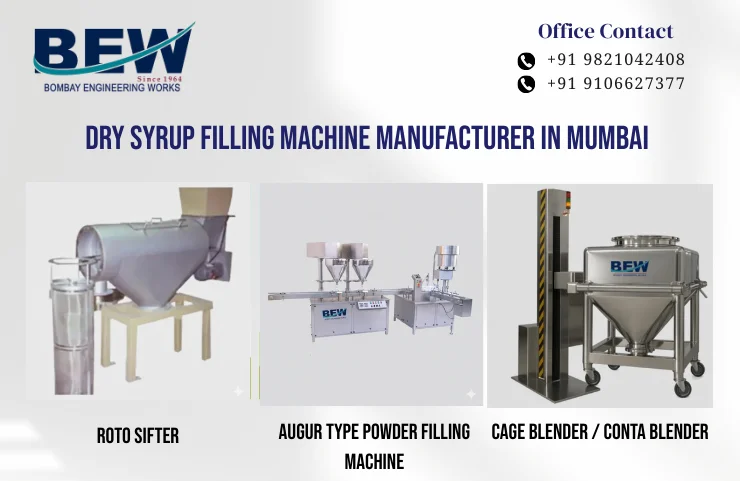

Complete Range of Dry Syrup Section Machinery by Bombay Engineering Works

To build a fully functional dry syrup production line, BEW provides an entire range of machinery, each designed for precision and efficiency.

1. Dry Syrup Powder Filling Machine

This is the heart of the dry syrup section.

Key Features:

- High-accuracy auger filling

- Servo/ clutch-based filling mechanism

- Stainless steel contact parts

- No bottle – no fill mechanism

- Tool-less adjustment

- Digital controls for weight accuracy

- Zero-dust emission design

Benefits:

- Ensures precision dosing

- Prevents product wastage

- Enhances production speed

- Reduces human error

2. Bottle Cleaning Machine

Before filling, bottles must be cleaned thoroughly to avoid product contamination.

Features Include:

- Internal and external bottle washing

- High-pressure air jets

- Water rinsing system

- Fully automatic conveyor system

Benefits:

- Maintains hygiene

- Ensures sterile preparation

- Complies with GMP standards

3. Bottle Inspection Conveyor

A crucial step where the bottles pass through for manual or automated inspection.

Features:

- High-speed conveyor

- LED backlight for easy visibility

- Adjustable height

Benefits:

- Detects defective bottles

- Eliminates contamination risks

4. Cap Sealing Machine

After filling, bottles are sealed with precision.

Types Available:

- Screw capping machine

- ROPP capping machine

- CRC capping machine

Key Features:

- Torque adjustable

- High-speed sealing

- Stainless steel body

Benefits:

- Leak-proof sealing

- Reliable and consistent results

5. Labeling Machine

BEW offers labeling machines suitable for:

- Round bottles

- Square bottles

Features:

- High-speed applicator

- PLC-based controls

- Online print and verification system

Benefits:

- Accurate label placement

- Better branding and batch traceability

6. Packing Conveyor

A stainless-steel conveyor system that moves sealed and labeled bottles toward the packing section.

Benefits:

- Smooth operation

- Enhanced productivity

- Efficient handling

How Bombay Engineering Works Ensures EEAT Standards for Accurate, Authoritative & Trustworthy Content

Experience

Real-world insights about BEW’s 50+ years of manufacturing.

Expertise

Technical explanation of machinery and production line.

Authoritativeness

Highlights BEW as a trusted and established manufacturer since 1964.

Trustworthiness

Accurate, transparent, and brand-focused information.

Industries Served by BEW’s Dry Syrup Machinery

Although primarily used in the pharmaceutical industry, BEW machinery also supports:

- Nutraceutical manufacturing

- Ayurvedic and herbal formulations

- Food supplement powders

- Veterinary medicines

- Chemical industries

This makes it a multi-industry compatible solution.

Advantages of Choosing BEW as Your Dry Syrup Section Machinery Supplier in Vasai

High Accuracy in Filling

BEW’s servo-controlled auger filling ensures ±1% accuracy.

Availability of Custom Filling Capacity

From 5 g to 100 g or more custom dosing available.

GMP-Compliant Design

Smooth surfaces, SS-316 contact parts, easy cleaning.

Low Energy Consumption

Machines are designed for efficient operations.

Long Operational Life

Sturdy construction ensures years of uninterrupted use.

Full Technical Support

Dial 9821042408 anytime for support.

Frequently Asked Questions

Q1. What is a dry syrup filling machine?

Ans: It is a machine used to accurately fill powder-based medicines into bottles in a hygienic, GMP-compliant way.

Q2. Why choose Bombay Engineering Works?

Ans: Bombay Engineering Works offers 50+ years of expertise, GMP design, durable machinery, and reliable support.

Q3. Can the filling capacity be customized?

Ans: Yes, Bombay Engineering Works provides fully customizable dosing options to match your production needs.

Q4. Are the machines easy to maintain?

Ans: Yes, the machines are designed for low maintenance, long life, and smooth operation.

Q5. How can I get a quote?

Ans: You can contact Bombay Engineering Works at 9821042408 for pricing and details.

Contact Bombay Engineering Works Today

Address: Unit No. 9, Unity Industrial Estate, Naikpada, Valiv Village, Near Ganesh Mandir, Vasai East, Dist: Palghar-401208.

Phone: +91 9821042408 / +91 9106627377

Email: info@bombayengg.com / admin@bombayengg.com / support@bombayengg.com

Website: www.bombayengg.com

Conclusion

If you’re looking for reliable, high-performance, and GMP-compliant Dry Syrup Section Machinery Manufacturers in Vasai, then Bombay Engineering Works is undoubtedly your best choice. With over 50+ years of experience, advanced engineering, unmatched quality, and excellent customer support, BEW ensures that your pharmaceutical production line operates smoothly, efficiently, and in full compliance with industry standards.

Whether you need a complete dry syrup production line or a single machine, BEW delivers with precision, passion, and perfection.

For quotes, demos, or consultations, call 9821042408 today.