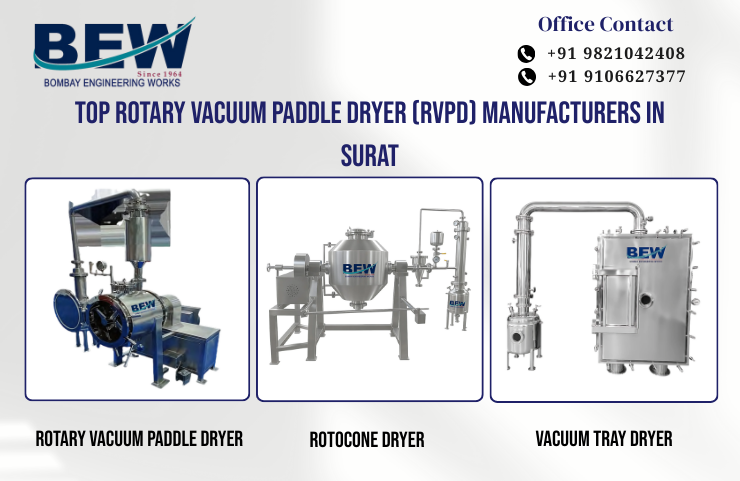

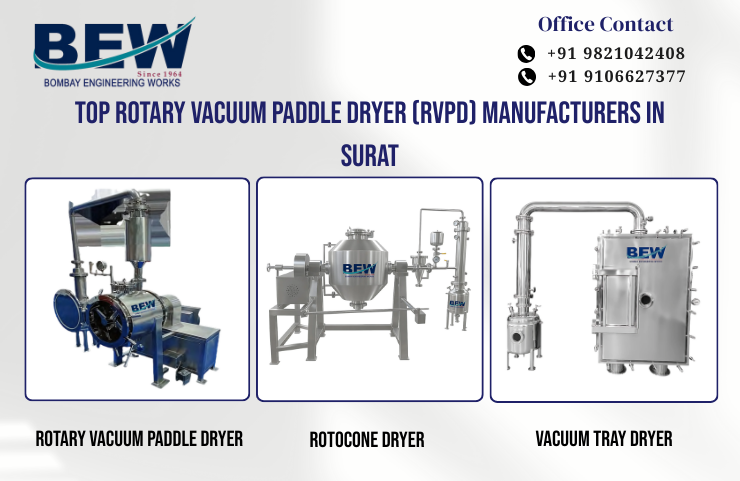

Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat

Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat Bombay Engineering Works – Delivering Excellence Since 1964

When it comes to efficient drying solutions in the pharmaceutical, chemical, food, cosmetic, and herbal industries, choosing the right equipment manufacturer is crucial. After all, the performance of your production line depends heavily on the reliability, precision, and efficiency of your machinery.

If you are searching for the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat, you are in the right place. Bombay Engineering Works, established in 1964, has built a strong reputation for manufacturing high-performance industrial machinery that meets global standards.

Call us today: 9821042408

About Bombay Engineering Works – A Legacy of Trust Since 1964

Established in 1964, Bombay Engineering Works has been at the forefront of industrial machinery manufacturing in India. Over the years, the company has earned the trust of thousands of clients across industries.

What truly sets Bombay Engineering Works apart is its commitment to:

- Engineering precision

- Innovation

- Quality control

- Customer-centric solutions

- After-sales support

With a wide product portfolio including Pharmaceutical Machinery, Chemical Machinery, Food Processing Machinery, Cosmetic Machinery, and Ayurvedic & Herbal Machinery, the company offers complete process solutions under one roof.

Understanding Rotary Vacuum Paddle Dryer (RVPD)

Before choosing a manufacturer, it is important to understand what a Rotary Vacuum Paddle Dryer actually does and why it plays such a vital role in modern industries.

A Rotary Vacuum Paddle Dryer (RVPD) is an industrial drying system used to remove moisture from wet materials under vacuum conditions. Because drying happens under reduced pressure, the boiling point of liquids decreases, allowing materials to dry at lower temperatures. This is especially beneficial for heat-sensitive products.

Key Benefits of RVPD:

- Low temperature drying

- Energy efficiency

- Uniform heat transfer

- Minimal product degradation

- Faster drying cycle

- Reduced oxidation risk

Therefore, industries that deal with pharmaceuticals, chemicals, food ingredients, and herbal products rely heavily on high-quality RVPD systems.

Why Surat Industries Demand Advanced RVPD Systems

Surat is one of India’s major industrial hubs. It houses pharmaceutical companies, chemical manufacturers, dye industries, and food processing units. As these industries continue to expand, the demand for advanced drying systems also increases.

Moreover, manufacturers in Surat require:

- Hygienic design for pharma applications

- Corrosion-resistant materials for chemical processing

- GMP-compliant machinery

- Energy-efficient operations

- Long-lasting equipment

This is precisely why companies searching for the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat turn to Bombay Engineering Works.

Why Bombay Engineering Works is Among the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat

1. Decades of Engineering Expertise

With more than 60 years of experience, Bombay Engineering Works understands industry-specific drying requirements. As a result, every RVPD unit is designed with practical industry insights and technical precision.

2. High-Quality Construction

The Rotary Vacuum Paddle Dryers are manufactured using:

- SS 304 / SS 316 / SS 316L

- Heavy-duty paddles

- Robust gear systems

- Vacuum-tight construction

Consequently, the machines ensure durability, corrosion resistance, and long service life.

3. Custom-Built Solutions

Every industry has unique requirements. Therefore, Bombay Engineering Works offers customized RVPD solutions based on:

- Batch size

- Material properties

- Moisture content

- Temperature sensitivity

- Production capacity

This flexibility makes the company one of the most preferred RVPD manufacturers serving Surat industries.

4. Energy Efficiency & Cost Savings

Because RVPD systems operate under vacuum, they consume less energy compared to conventional dryers. Furthermore, optimized paddle design ensures uniform heat distribution, reducing drying time.

Over time, this results in significant operational cost savings.

5. GMP & Industry Compliance

For pharmaceutical and herbal applications, compliance is non-negotiable. Bombay Engineering Works manufactures RVPD units following industry standards and hygienic design practices.

Applications of Rotary Vacuum Paddle Dryer

The versatility of RVPD systems makes them ideal for multiple industries.

Pharmaceutical Industry

- API drying

- Intermediates

- Bulk drugs

- Heat-sensitive compounds

Chemical Industry

- Dyes

- Pigments

- Fine chemicals

- Organic compounds

Food Processing Industry

- Nutritional powders

- Herbal extracts

- Spices

- Food additives

Cosmetic Industry

- Cosmetic powders

- Active ingredients

Ayurvedic & Herbal Industry

- Herbal extracts

- Natural powders

- Plant-based materials

Therefore, if you are operating in Surat and looking for a reliable drying solution, choosing one of the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat becomes essential for your production success.

Technical Features of Bombay Engineering Works RVPD

Here are some advanced features that make their dryers stand out:

- Efficient paddle agitation system

- Jacketed vessel for uniform heating

- Vacuum pump integration

- Condenser and receiver system

- Low RPM for gentle mixing

- Fully automated control panel (optional)

- PLC-based operation (optional)

- Easy discharge system

Additionally, safety mechanisms are incorporated to ensure smooth and secure operations.

Quality Assurance & Testing

Quality is not just a promise at Bombay Engineering Works; it is a practice.

Each Rotary Vacuum Paddle Dryer undergoes:

- Material inspection

- Weld quality testing

- Vacuum leakage testing

- Trial run before dispatch

As a result, customers receive machinery that performs reliably from day one.

How to Choose the Right RVPD Manufacturer in Surat

Before finalizing a supplier, consider the following:

- Experience in the industry

- Material quality used

- Customization options

- Compliance with standards

- After-sales service

- Client testimonials

- Technical expertise

When evaluated on these parameters, Bombay Engineering Works consistently ranks among the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat.

Installation & After-Sales Support

Buying machinery is just the beginning. Proper installation and ongoing support determine long-term efficiency.

Bombay Engineering Works offers:

- On-site installation assistance

- Operator training

- Technical consultation

- Spare parts availability

- Quick service response

Why Businesses in Surat Trust Bombay Engineering Works

Surat’s industrial growth demands reliable partners. Over the years, Bombay Engineering Works has supplied machinery to various industrial clusters across Gujarat.

Clients appreciate:

- Transparent pricing

- Timely delivery

- Strong technical support

- Durable machinery

- Ethical business practices

Therefore, when businesses search online for the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat, Bombay Engineering Works consistently emerges as a trusted name.

Customer Support: 9821042408

Frequently Asked Questions (FAQs)

Q1. What is the capacity range of Rotary Vacuum Paddle Dryers?

Ans: Capacity can vary based on client requirements. Bombay Engineering Works offers customized capacity options depending on production needs.

Q2. Is RVPD suitable for heat-sensitive materials?

Ans: Yes. Since drying occurs under vacuum, lower temperatures can be used, making it ideal for heat-sensitive materials.

Q3. Does Bombay Engineering Works provide installation services in Surat?

Ans: Yes, the company provides installation assistance and technical support.

Q4. What materials are used for manufacturing RVPD?

Ans: Commonly SS 304, SS 316, and SS 316L are used depending on application requirements.

Q5. How can I contact Bombay Engineering Works?

Ans: Simply call us at 9821042408 or visit www.bombayengg.com.

Contact Bombay Engineering Works Today

Address: Unit No. 9, Unity Industrial Estate, Naikpada, Valiv Village, Near Ganesh Mandir, Vasai East, Dist: Palghar-401208.

Phone: +91 9821042408 / +91 9106627377

Email: info@bombayengg.com / admin@bombayengg.com / support@bombayengg.com

Website: www.bombayengg.com

Conclusion

If you are searching for the Top Rotary Vacuum Paddle Dryer (RVPD) Manufacturers in Surat, Bombay Engineering Works stands as a trusted and experienced name in the industry. With a legacy dating back to 1964, the company combines engineering excellence, modern technology, and customer-focused service.

Whether you operate in pharmaceuticals, chemicals, food processing, cosmetics, or herbal manufacturing, Bombay Engineering Works delivers high-performance drying solutions tailored to your needs.

Contact Bombay Engineering Works today: 9821042408

Website: www.bombayengg.com