checkout the blenders

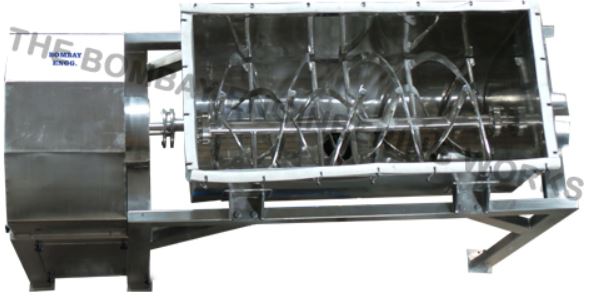

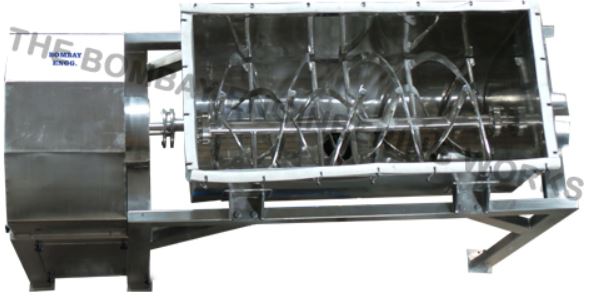

In the U shape container, there are positive and negative ribbons. The rectification of a particular proportion of two ribbons with the kind of material, quantity, and balance of the body. The ribbon blender or the ribbon mixer has a good effect on mixing viscosity or cohesion powder. and used for a mixer of powder; it is also known as a blender machine

Our company provides various sealing devices according to the difference in materials. The standard sealing structure is a stuffed seal and also called the TEFLON seal. After using it for a period, the user(s) should fasten and enhance it. However, the dynamic seal has a long-time sealing effect and is especially fit for the powder, liquid.

Two types:

There is a discharging valve at the bottom of the mixer body. When mixing different types of materials, we use a flat discharging valve. The discharging valve’s operation should be convenient, and there are three types: Manual, air-driven, and electricity-driven. The manual discharging is operated on the valve, and the open extent is controlled by hand freely. The air-driven discharging valve, assembled with a cylinder, works under air pressure. The electricity-driven discharging valve works under the control of the electricity control box.

We can use a jacket when heating, cooling, or heat-preservation is needed. The jacket filled by circulation and heat conduction medium and can not bear high pressure. There are two kinds of heat conduction medium: Water and oil. Should limit the water temperature to 90, and should determine the oil temperature at 300. The jacket coordinates the external heating system, the expulsion system, the pipeline to carry on to the material, and even temperature processing.

| Model | Gross Volume Ltrs | Working Volume Ltrs |

Output Speed |

Motor H.P. |

Discharge Valve | Overall Dimensions | ||

| Width mm | Depth mm | Height mm | ||||||

| RIB 5 | 17 | 10 | 0.5 | 70 | 4″ | 800 | 300 | 600 |

| RIB 10 | 28 | 20 | 0.5 | 70 | 4″ | 900 | 350 | 1000 |

| RIB 25 | 80 | 50 | 1 | 70 | 4″ | 1100 | 450 | 1000 |

| RIB 50 | 130 | 100 | 1.5 | 70 | 4″ | 1800 | 600 | 1200 |

| RIB 100 | 290 | 200 | 3 | 60 | 4” | 2000 | 700 | 1300 |

| RIB 250 | 320 | 500 | 7.5 | 55 | 6″ | 2500 | 750 | 1400 |

| RIB 500 | 1300 | 1000 | 10 | 45 | 8″ | 450 | 450 | 450 |

| RIB 750 | 1900 | 1500 | 15 | 35 | 10″ | 3500 | 1000 | 1600 |

| RIB 1000 | 2500 | 2000 | 20 | 35 | 12″ | 3600 | 1200 | 1700 |

| RIB 2000 | 4800 | 4000 | 2 | 25 | 12″ | 4200 | 1400 | 2600 |

| RIB 3000 | 7000 | 6000 | 40 | 20 | 12″ | 4800 | 1500 | 2700 |